I am in pure ecstasy at the moment! It is a rush I only had a few

times before. Bumping a wide variety of locks for the first time was

one of them. The other rushed I can not disclose on this public forum …

But seriously, I am still a little in shock too.

This weekend I did my first serious attempt to impression an Abus lock.

Looking at the book and the marks on the key I knew I was on the right track.

But I did not open the lock…

Monday Paul Crouwel and myself went to Hamburg to meet with Oliver Diederichsen.

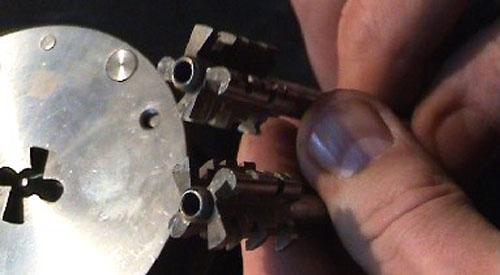

We had a nice meeting with him and besides a private impression workshop he did

show us lots of nice things. I shot quite some video, so make sure to check

blackbag regularly these days to come. You will enjoy it … that is a promise!

When I came home from work today I stopped at a shop and bought a nice

magnifying lamp. It is a valuable tool when impressioning locks.

Right after dinner I started… my goal was to open at least one lock!

My first try was immediately successful! Within ten minutes the first

Abus opened! The marks were so clear and obvious, I could not believe it.

And still I can not believe it 😉

Second was another Abus, one I did know what the key looked like a

bit. I vaguely remembered it had some ‘high low high’ combination but

I tried not to think about that too much. I focused on the marks and

when I got somewhere the key broke ‘half way’. Filing the remaining

marks on the key did not open the lock.

Because the key was very fragile I had to try something else. So instead of

moving the key up and down, I moved the key in and out, making horizontal marks

instead of pointed marks. I could clearly see the long-marks and filed two more

rounds. The next time I pulled the key in and out, the lock opened!

So I had a score of two out of two! It was time to put the kids to bed.

When I finished that ‘job’ I optimisticly started digging trough my collection for

other locks with the correct blank. I could only find a Corbin … brrr …

Unfortunately the depths of Corbin are not in the book so I had to file in

much smaller steps. The first key I tried I went too deep to fast. But the

second key I remained my focus and … succeeded in opening the lock!

This was the ultimate rush. Unknown depth steps and still success.

Last but not least I found a CES lock and blank. Again I used the book

for depth measurements. It also opened the first try.

In two hours time I opened four locks using only five blanks, and put

the kids to bed too. Now siting at my couch thinking it all over.

I only hope it is not a dream … it feels a little like it!

Tomorrow is the Toool Amsterdam meeting. I will bring some impressioning

materials so members can try it themselves.

Update 01:25 am : Back to earth. Tired and off to bed. Tried to open a DOM lock without success ….