One thing that always fascinates me is high security keys and restricted keyblanks. And I always keep an eye out for new techniques and profiles.

The image above shows two keys to the (relatively new) EVVA ALS system. As you can see EVVA removed some material from the tip of the key, making that part much thinner. Flattening the tip is done by more manufacturers, like the Nemef/CES on the Dutch KM profile, and I was really curious how they made the core more thin on the tip. So when a friend got his hands on an EVVA ALS demo lock I could not wait to take it apart.

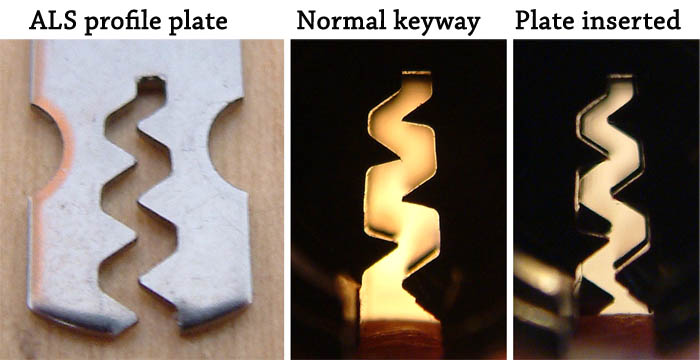

The solution by EVVA is clever … as always. They just milled a thin slot between pin 4 and 5, and inserted a small metal plate with the ‘thin tip profile’. A simple and elegant way of making your keyway more narrow. The image above shows you the keyway with and without the plate inserted.

The interesting thing is that if you make a key that is entirely as thin as the tip part, it will get stuck at the plate. The wide part of the original key will align the thin part right in front of the plate, while a complete thin one will hit the walls of the plate and need some jiggling to enter all the way.

All in all a pretty clever design …

how then, would you pick this thing?

iceman: using a very fine/slim fingerpick? 😉

Barry, will a small Easy-Entrie Blank work?

Steffen

Steffen: Yes it will work, but it will require some jiggling when the tip reaches past pin 4.

This reminds me of special keyways for Abloy Disklock/etc. locks, where the 0 profile disc is slightly different than the 7 profile disc, such that extra cuts at the tip of the key are required for the key to fit all the way into the lock.

If an Easy-Entry was used twice on a blank (the second run would require a non-standard way of fastening the blank), a perfect fitting key could be made?