I (Walter) have created a geocache that requires some RSA hacking and subsequently lockpicking. I bought an Abus Titalium 64TI/40 padlock to be picked. Several people were able to find it by teaming up together. The feedback I got was that people spent considerable time on the lock, sometimes several hours (in separate sessions).

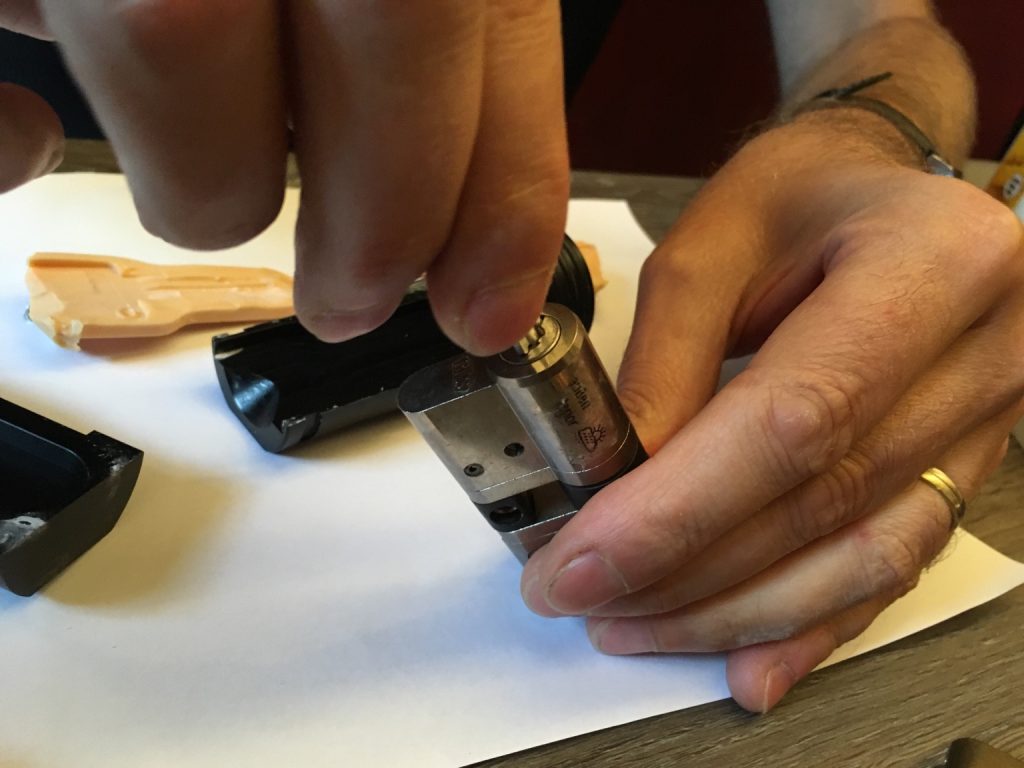

Geocacher #15 was unable to lockpick the lock, even though he had practiced on an identical lock at home. I offered to go with him to give advice. He couldn’t open it. Also I couldn’t (quickly) open it. I took the original key and that would not open it. By not fully inserting the key and wiggling, I succeeded in opening. (I let the geocacher pick his own lock and allowed him to log the cache.)

Once home, I decided to take a look at the lock. Although only a very limited number of people had worked on it, it was completely shot. I took a video comparing showing a new padlock and then the one from the cache:

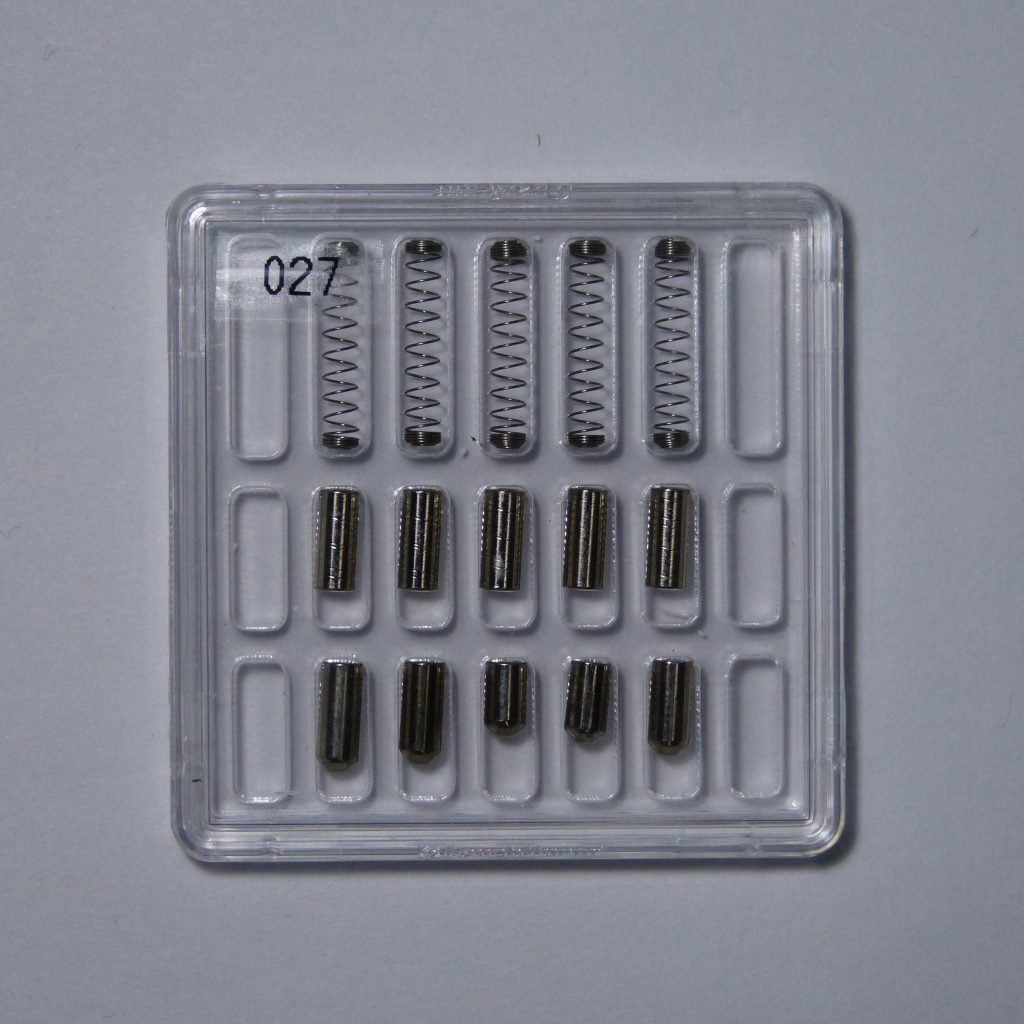

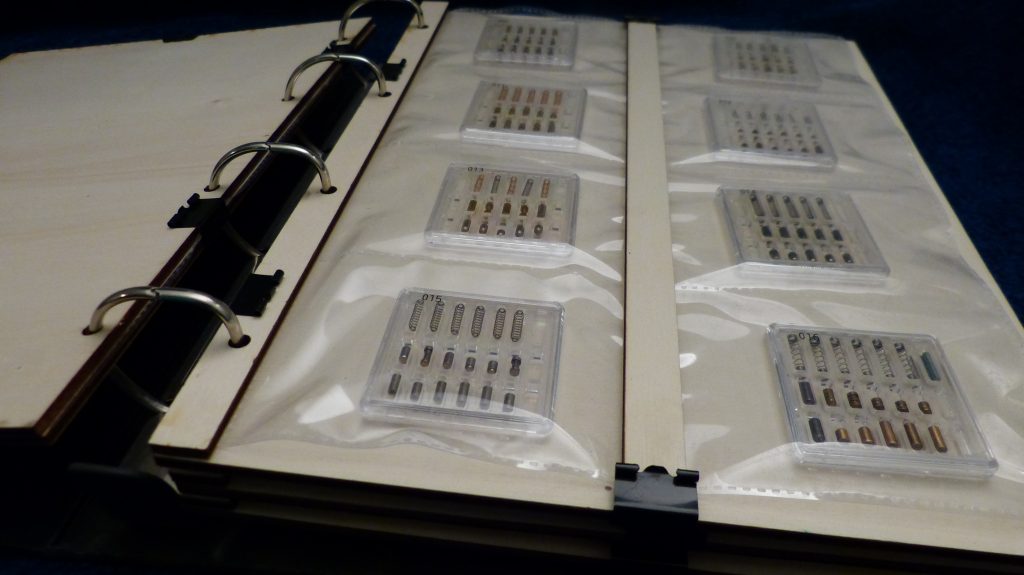

I’ve taken apart the lock to have a look at the pins. We always say that picking a lock will leave tiny traces on the pins (and other parts of the lock) that can be found during a forensic investigation. Well, in this case, the naked eye was enough to see the abuse.

Here’s the plug with the key inserted. Note how the pins have shortened. This causes the key to no longer work.

This also explains why taking out the key a bit and wiggling opened it.

Here’s a view of the pins:

There’s now a new padlock in place. You can’t really tell from the picture here, but the pins are made out of aluminium, which kind of explains the wear on them. I bought the lock as it is marketed as being weather proof. But resisting weather is different from resisting lockpicks.

Photos/video CCBY4.0 Walter Belgers