In an effort to quantify the locksport world, I’m taking my measuring tools to locksport in an attempt to learn the details. For example, how much torque is required to pick a lock. With this knowledge, we can build better lockpicks, and teach proper technique. In this blog, I’ve set out to compare the hardness of key blanks for impressioning.

As I’m not a machinist, nor do I have access to fancy hardness measuring equipment, I’ve found the cheapest method I could use at home. There are many methods, and many systems, to measure the hardness of metal. One difficulty was to get familiar with the lingo and to find a measurement tool that works for key like metals, thin, soft, etc.

The most common method of cheap hardness testing is to use Rockwell hardness testing files from measuring hardness of knifes. Usually in the range of C40 to C65 in increments of five. I’ve found similar methods online for testing the hardness of lead with pencils. Where HB hardness pencil will be equivalent to a certain percentage lead in tin. To my knowledge, none such system exists for brass.

More expensive methods press a hardened piece of metal with a known force into the sample, and measuring the indentation. While most of these measuring jigs are too expensive, I’ve found one for cheap. That is the Poldihammer test, which is sold on eBay for around €100. The tool uses a captive ball bearing which presses both on a bar of known hardness and the sample. You just simply place it on the object and hit it with a hammer. The ball bearing presses with equal force into both metals object. Comparing the dents gives you the Brinell hardness.

My Poldihammer came with a small magnifier and scale. It’s not so easy to use, and the resolution is minimal. The kit also comes with convention tables, but they feel very approximate. My solution is to measure the indentation with a digital microscope and calculate the BHN from this formula from Wikipedia:

BHN = Brinell Hardness Number (kgf/mm2).

P = applied load in kilogram-force (kgf)

D = diameter of indenter (mm)

d = diameter of indentation (mm)

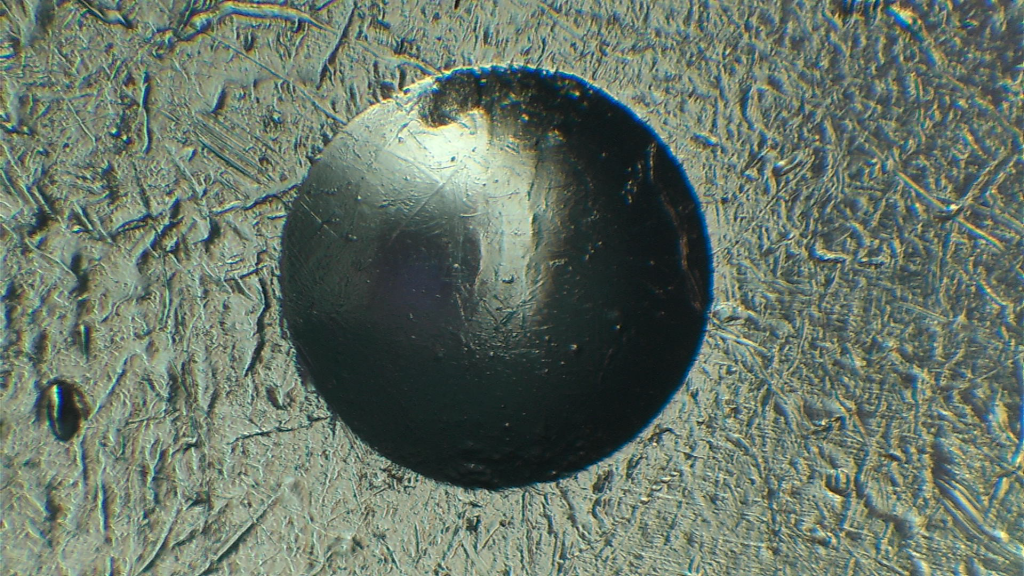

It doesn’t take much to use the dent on the reference bar to calculate the force. As the force is equal on the key, we can use the force to calculate the hardness of the keys. Let’s take a look at a real world example. The next two images are the dents under high magnification.

For completeness, I’ve added the calculations as to make the method repeatable, and accessible to more hobbyists. The force is calculated as follows: P = BHN(reference) * PI * D * (D – SQRT(D^2 – X^2)). Where X is the dent on the reference bar. In LibreOffice Calc, this is =187*PI()*10*(10-SQRT(10^X^2)).

The hardness of the key is calculated BHN(Key) = P /(PI * D *(D^2-Y^2)). Where Y is the dent on the key. In LibreOffice Calc, this is =P/(PI()10(10-SQRT((10^2)-(Y^2))))

For the numbers above, I’ve found the force as 706.25, and the BHN of the key as 110.8. I’ve repeated the test for four more keys and measured them as 114.5, 103.9, 97.0, and 118.2 with an average of 108.9. In similar measurements, I would drop the minimum and maximum and take the average of the remaining samples, which is 109.7.

The following table is the result of my measurements. The results are surprising.

| Brand | Average | Aquired date | Comment | Measurement [BHN] |

| Silca | Three keys | 2018 | CS206 Brass. | 147.1 |

| Silca | Three keys | 2022 | LD5R Steel. | 222.8 |

| JMA | Three keys | 2018 | Keys from Nigel Tolley. | 135.4 |

| Bauelemente | Three keys | 2019 | SSDeV Impressioning. | 123.5 |

| Abus | Three keys | 2019 | LockCon | 133.4 |

| Abus | Three keys | 2020 | Toool Inventory | 135.8 |

| Abus | Five keys | 2022 | LockCon Box A | 127.4 |

| Abus | Five keys | 2022 | LockCon Box B | 108.9 |

| Abus | Five keys | 2022 | LockCon Box C | 131.5 |

The data revealed something interesting and confirmed a hunch. The hardness of steel keys is the highest, obviously. We see the brass alloy (nickel silver) have a range of values. There are also outliers, for example Box B, these keys are softer than keys acquired on the same day.

I’ve since played with both harnesses and can tell one hardness from another in impressioning. But only after I’ve switched from one hardness to another after a dozen opens, with the same hardness. After switching backwards and forwards, I can’t tell the difference in a blind test.

One final note, the kit comes with one reference bar that is consumable. We have about a hundred measurements in them. I have not found replacement bars, yet. But I believe we can use a similar shaped bar of steel, which is then calibrated with the reference bar before use. This will reduce accuracy, but can be accounted for if the measurements are comparative.

Thanks for taking your time to read about measuring hardness of keys. If you have a professional (Brinell) hardness measurement tool, and want to help out, let’s swap keys and compare notes. I’m always open to learn.