So … back from Las Vegas and still not fully recovered from it. The heat is overwhelming there, and recovering two jetlags in a couple of weeks is taking it’s toll.

But nevertheless we had an extremely good time and learned to know a lot of people. Besides the people I already knew, the people from ‘Fool’ pleasantly surprised me. Very friendly, very knowledgeable, and most important: they seem to have ‘the drive’. Hopefully they will make it to the Dutch Open in Sneek this year. We are currently very busy planning the Open, and next week’s posting will be a long one informing you about it.

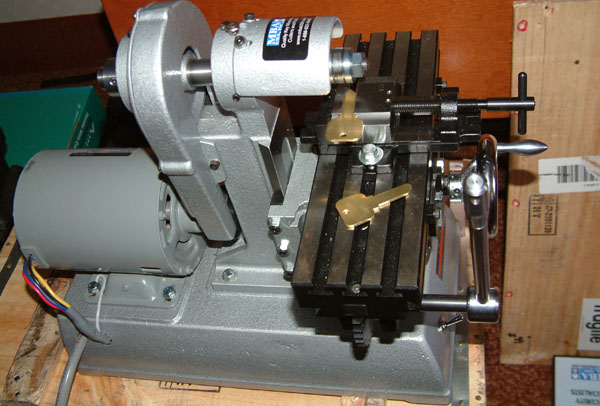

As always my suitcases were loaded to their limit when coming back. Got a lot of tools and gadgets, and a lot new blanks for my collection. But what is more important is that I now got a device to create my own blanks! I took advantage of the low dollar and purchased a ‘keyway king‘. It is a horizontal milling machine that comes with 16 different cutting wheels. The idea is you measure the cuts in an existing key or keyway and then try to reproduce them on an uncut key (a true blank with no grooves in it). It is also an ideal machine to cut grooves in existing blanks as some manufacturers only use a few ‘basic blanks’ and just take away some grooves to make them fit one specific profile.

The device is currently still in the US as it was too heavy to carry with me. And a very good friend is making modifications to this machine that will make it much more easy to use and will ship it when he is ready. Of course I will share the details on how he modified it with you when the device arrives …

Now packed my bags for a few day’s Berlin. At least I will be in the same timezone now ….

I’m wondering what the modification will be… First thing that comes to my mind would be a mod to be able to cut grooves under a certain angle, so you’ll be also able to create those type of blanks that the Easy Entrie cannot copy.

Now thats a short manual! The machine looks great and will be exciting to see what you can churn out.

I don’t believe they are adding additional functionality like undercut grooves Tom, just making it easier to use and reproduce the same results on future blanks.

Hmm nice machine, although is copying restricted keyways a sure thing or a probability ?

Nice blog by the way Barry.

Looks like a lovely machine. Except for the electrics! The two holes the wires pass through are obviously meant to have strain-reliefs fitted. Adding those before any vibration chafes through the insulation on those wires would be my primary concern.

Small angle vises are not very expensive and should do fine for undercuts.

Cheers,

mh

Oh sweet machine! 😛 Barry, do you plan to try to cut Abloy key profiles with it?

Nice machine!

It reminds me to the Pink Box (http://www.pink-box.de/). But I think your machine has a lot better price-performance ratio!

If someone sould modify it for me, I would ask him to adapt the machine to the european electrics (plugs, voltage etc.). And at least make the wires look more safe. Some isolation, protection against chafeing through the isolation…

Cheers,

André

Barry, how much for each blank? Are they made of clean brass or something beter?

This machine is made in watayosi company, and it is a Japanese product.

It is a very reliable machine spreading for a long time among the Japanese locksmiths.

Looks like the cutters are sold individually by MBA so for those on a budget: a harbour freight mini-mill and right angle plate could probable be used to get the job done.

A lathe could also be used with some creative tool post work but to make that tool post would probably require a mill. There are after market z-axis tool posts which could be made to work if someone wanted.

TOWCH, converting for example a mini lathe is easy: Just make a key holder that can be tightened to the place of the toolpost with the provided M10 bolt. You can eaily adjust the cutting depth with shims, for example from spark plug gap gauge. Not the best solution, but easy to make 🙂

This machine is made in watayosi company, and it is a Japanese product.

Key milling machine